Hot Sale Poultry Farm A Type Full Automatic Egg Chicken Layer Battery Cages Nigeria

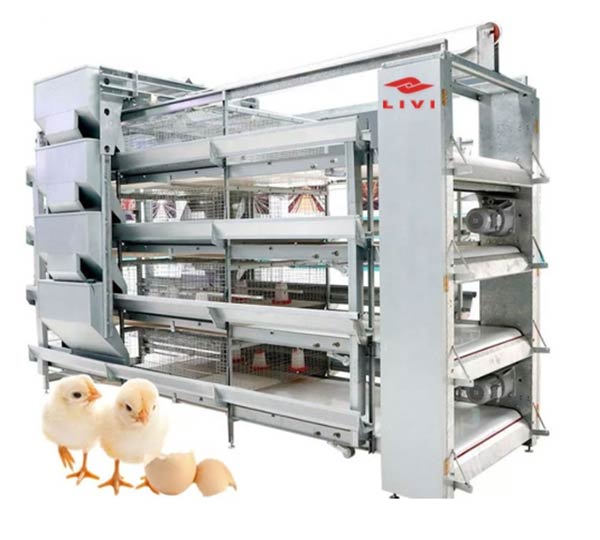

Product: Full Automatic A-type Egg Chicken Layer Battery Cages

Tiers: 4

Capacity: 160birds/set

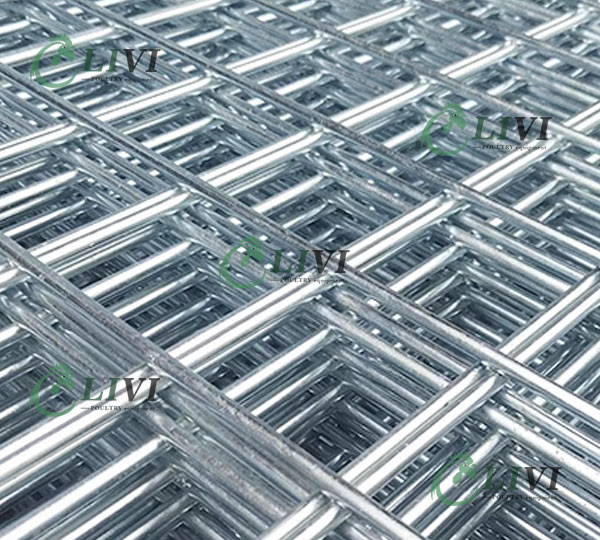

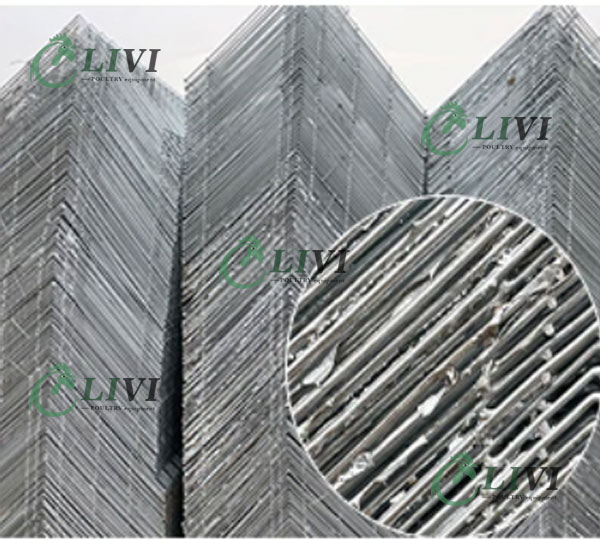

Material: Hot galvanized, cold galvanized (according to customers’ requirement)

Application: medium-sized and large scale layer house

Lifespan: Last 20-30 years

Sales volume: Customers cover 80+ countries

Certificate: ISO9001, CE, SGS, SONCAP

Introduction of Full Automatic Egg Chicken Layer Battery Cages

The A Type Chicken House Layer Battery Cage with Full Automatic Poultry Feeding Equipment is a cutting-edge solution designed to optimize egg-laying chicken management in poultry farms. This system integrates A Type battery cages with advanced automatic feeding equipment, revolutionizing the feeding process for maximum efficiency and convenience.

With this setup, poultry farmers can enjoy hands-free feeding operations, as the system automatically dispenses feed to the chickens at pre-programmed intervals. This not only saves time and labor but also ensures consistent and precise feeding, promoting optimal growth and egg production.

Dimension of Full Automatic Egg Chicken Layer Battery Cages

| LAYER CAGE | 90 CAGE | 96 CAGE | 120 CAGE | 128 CAGE | 160 CAGE |

| Feeding Quantity | 90Pcs | 96 Pcs | 120 Pcs | 128 Pcs | 160 Pcs |

| Cage Size | 1950*350*380mm | 1950*350*380mm | 1950*350*380mm | 1950*350*380mm | 1950*450*410cm |

| Tiers | 3 | 3 | 4 | 4 | 4 |

| Doors | 4 | 4 | 5 | 4 | 4 |

| Birds/Door | 4 | 4 | 3 | 4 | 4 |

| Space /Bird | 455cm2 | 426.5cm2 | 455cm2 | 426.5cm2 | 438.75cm2 |

| Cage Height | 1.39M | 1.39M | 1.83M | 1.83M | 2M |

Features of Full Automatic Egg Chicken Layer Battery Cages

- Automated Feeding: These battery cages are equipped with automatic feeding systems that dispense feed to the chickens at scheduled intervals, ensuring consistent nutrition and reducing labor costs.

- Automatic Watering: They also feature automatic watering systems that provide a continuous supply of clean water to the birds, ensuring optimal hydration and minimizing manual watering efforts.

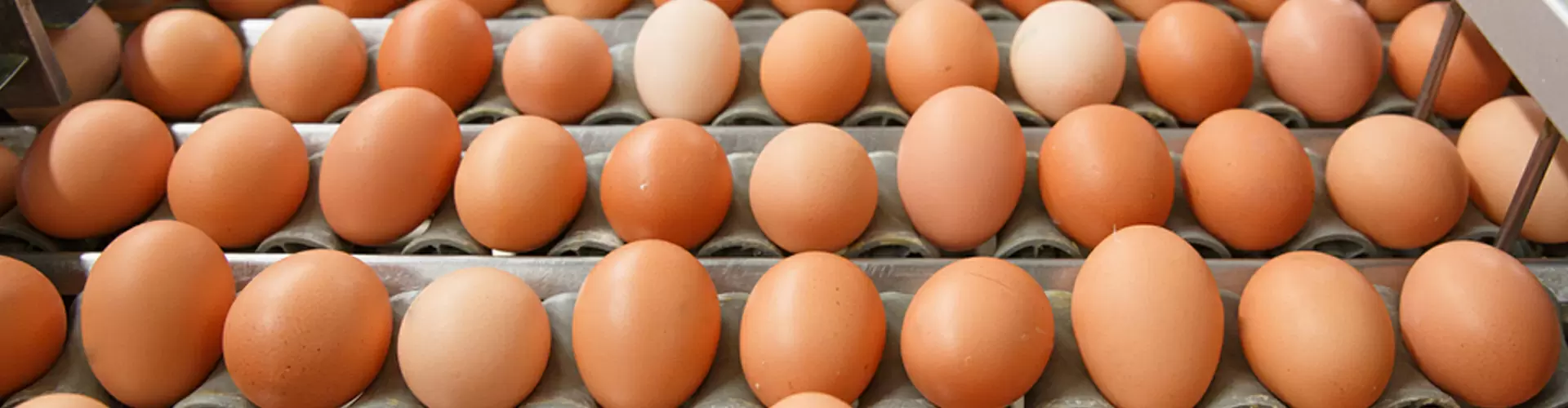

- Egg Collection Automation: The cages incorporate automatic egg collection systems, which gather eggs from the cages without manual intervention, reducing labor requirements and minimizing the risk of egg damage.

- Space Optimization: Designed with a tiered structure, these battery cages maximize vertical space utilization within the poultry house, allowing for high-density housing while maintaining comfort and ventilation for the layers.

- Durable Construction: Constructed from high-quality materials, these battery cages are sturdy and long-lasting, providing a secure housing solution for layers and ensuring their safety and well-being.

- Easy Maintenance: The cages are designed for easy cleaning and maintenance, with removable trays and accessible surfaces, facilitating hygiene and sanitation in the poultry house.

Advantages of Full Automatic Egg Chicken Layer Battery Cages

- Increased Efficiency: Full automation of feeding, watering, and egg collection processes reduces manual labor requirements, saving time and resources for poultry farmers.

- Consistent Production: Automated systems ensure consistent nutrition and optimal conditions for the layers, resulting in higher egg production rates and improved overall efficiency.

- Improved Egg Quality: With automatic egg collection, eggs are promptly gathered from the cages, reducing the risk of breakage and contamination, resulting in higher-quality eggs.

- Space Utilization: The tiered structure of the battery cages allows for high-density housing, maximizing space utilization within the poultry house and increasing overall productivity.

- Reduced Labor Costs: Automation reduces the need for manual labor in feeding, watering, and egg collection, resulting in significant cost savings for poultry farmers.

- Enhanced Monitoring and Control: Some systems may offer remote monitoring and control capabilities, allowing farmers to monitor and adjust parameters such as feeding, watering, ventilation, and temperature from anywhere, enhancing operational efficiency and flexibility.

Usage of Full Automatic Egg Chicken Layer Battery Cages

Poultry Farms A Type Full Automatic Egg Chicken Layer Battery Cages are widely used in laying hen farms, which can increase egg production rate, save space, reduce the occurrence of diseases, and improve feed utilization.

Why Other Supplier’s Price is Cheaper?

Ours Cages

Hot-dip galvanized, anti-corrosion

Others Cages

Cold galvanized, easy to corrode

Ours Cages

Smooth surface, no hurt to chicken feet

Others Cages

Rough surface, easy to hurt chicken feet

Ours Cages

Sturdy and durable, with a load capacity of at least 300kg

Others Cages

Not durable and easily deformed, maximum load capacity of 150kg

Ours Cages

Feed trough with PVC material

Not easy to damage

Others Cages

Reclyle material and it is brittle which is easily damaged when used

How to install the Full Automatic Egg Chicken Layer Battery Cages

Installation of Poultry Farms A Type Full Automatic Egg Chicken Layer Battery Cages is very simple and can be installed according to the instructions. Or check out the installation video below.

How to manage the Full Automatic Egg Chicken Layer Battery Cages

Poultry Farms A Type Full Automatic Egg Chicken Layer Battery Cages are easy to maintain and only require regular cleaning and servicing.

Routine maintenance:

Check the cage regularly for damage or wear, and repair or replace it promptly if found.

Lubricate moving parts (such as drinkers and feeders).

Remove feces and dirt from the cage.

Check that waterers and feeders are working properly.

Observe the health status of the chickens and take timely measures if there are any abnormalities.

Regular maintenance:

Each quarter:

* Thoroughly clean and disinfect the cage.

* Check drinking and feeding systems and make necessary repairs.

* Check that cage doors and locks are working properly.

Per year:

* Complete cage inspection and repairs.

* Replace severely worn parts.

* Repaint or galvanize the cage to prevent rust.

Farm Cases of the Full Automatic Egg Chicken Layer Battery Cages

Abuja, Nigeria

10,000 laying hens farm

Lagos, Nigeria

15,000 laying hens farm

Ibadan, Nigeria

6,000 laying hens farm

Ogun State, Nigeria

20,000 laying hens farm

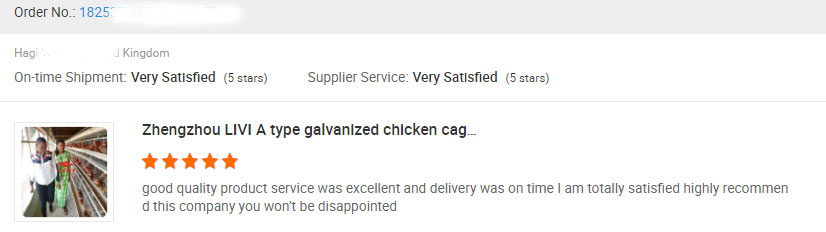

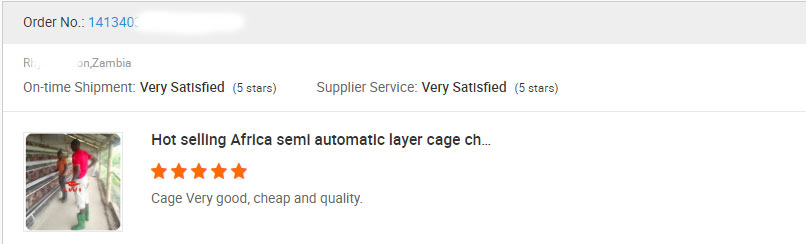

Feedback From Our Clients

Notes for Customers

Before purchasing, please contact us to understand the product specifications, performance and price.

When purchasing, please send us the payment voucher after payment to avoid the problem of entering the wrong account.

When installing, please install according to the instructions and make sure the installation is firm.

When in use, please clean and inspect the cage regularly to extend the service life of the cage.

If you have any questions, please feel free to contact us.

Tel: +86 150 9008 5057

WhatsApp: +86 150 9008 5057

Email: [email protected]