Battery cage poultry farming is on the rise in Ghana, becoming a catalyst for the transformation of the country’s agriculture sector. Individual projects, such as GH Farm, employing advanced a-type layer battery cage system have significantly boosted the industry.

GH Farm’s Modern Battery Cage Poultry Farm

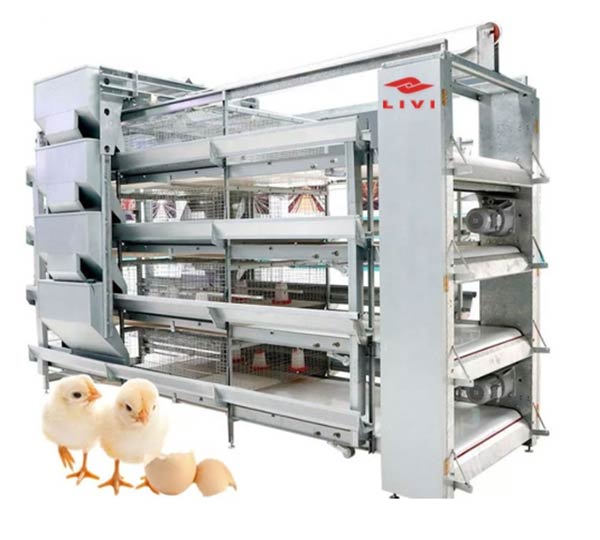

GH Farm’s layer hens are renowned for their high productivity and quality. The project’s 30,000 layers battery cage poultry farming operation utilizes a state-of-the-art a-type layer battery cage system, optimizing space utilization and enhancing the welfare of the birds.

Advantages of A-type Layer Battery Cage Systems

Layer battery cage systems offer GH Farm’s poultry operation several advantages, including:

- Increased Production: Layer battery cage systems accommodate more hens by optimizing space, thereby increasing production.

- Improved Health: Battery cage systems improve the hygiene for the birds, reducing disease transmission and leading to healthier chickens.

- Automated Feeding and Watering: The system features automated feeding and watering mechanisms, saving on labor and boosting efficiency.

Profitability for Customers Using A-type Layer Battery Cage System

Customers using a-type layer battery cage system from GH Farm have experienced significant profitability, including:

- Increased Revenue: Annual revenue increased by 20% to $100,000.

- Reduced Costs: Operational costs decreased by 15% to $60,000 due to automation and improved bird health.

- Increased Net Profit: Net profit increased by 55% to $40,000.

GH Farm’s 30,000 layers battery cage poultry farming operation stands as a testament to how this technology can lead to higher production, improved bird health, and substantial profits for its customers.