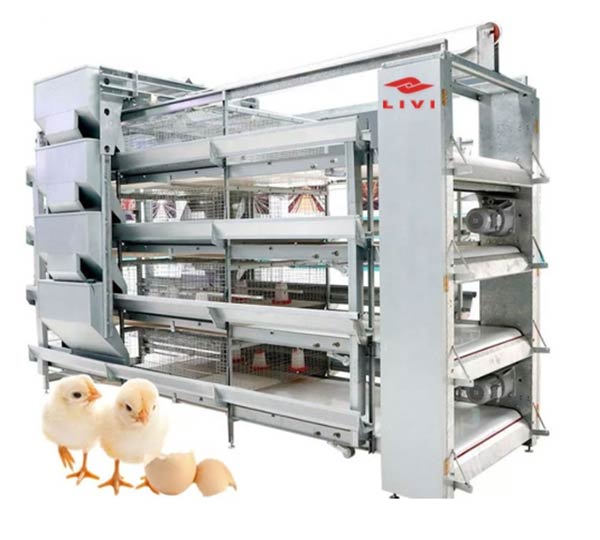

This 10,000 chickens poultry farm in the Philippines, using the automated layer cage system.

Project Details

- Project Name: 10,000 Chickens Layer Cage Poultry Farm in the Philippines

- Location: Cebu, the Philippines.

- Cage Type: 4-tier A-type layer cages, 160 birds/set, 2 rows/house, 32 sets/row..

- Number of chickens: 10,240 chickens in one poultry house

- Size of poultry house: 68m long, 8m wide.

Main Poultry Farm Equipment of This Poultry Farm in the Philippines

- Layer Cage System: A-shaped design, it saves site space to the maximum extent and improves the output and benefits of the chicken farm.

- Automated Management Equipment: Including automatic waterers, intelligent feeders, etc., which greatly reduce the burden of management and improve management efficiency.

Project Advantages by Using Automated Layer Cages

- Efficient space utilization: The design of the layer cage system allows more chickens to live and produce in a limited area. Thereby increasing the output and benefits of the chicken farm.

- Excellent sanitary conditions: Each chicken layer cage is carefully designed and maintained. It can keep the chicken house clean and tidy, and help to prevent the spread of diseases.

- Convenient management method: Automated management equipment greatly reduces the labor intensity of staff.

- Increase production and reduce losses: The design of the chicken layer cage greatly reduces the loss rate of eggs. It can increase the output and benefits of the poultry farm in the Phippines. Technical details and innovations

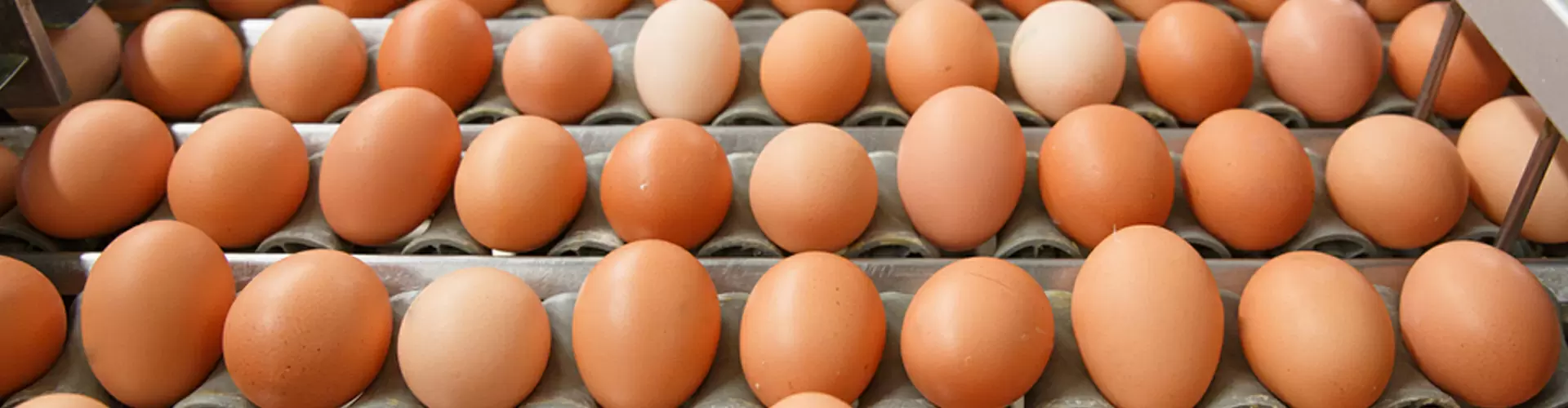

Production Data After Using Automated Layer Cages

- Egg production data:

- According to scientific statistics, the average daily egg production of each chicken can reach 0.9 eggs. And the average annual egg production can reach 328.5 eggs. Based on the breeding volume of 10,000 chickens, the daily egg production is about 9,000 eggs, and the annual egg production can reach 3.285 million eggs.

- Chicken growth:

- After scientific observation and recording, the Layer Cage system makes the chickens grow healthier and more stable.

- Egg quality:

- The egg quality is excellent, meeting the high standards of the market and customers.

Farming Cost After Using Automated Layer Cages

Here shows the farming cost of 10,000 chickens poultry farm in the Philippines below.

- Labor cost: Daily labor cost savings are about 8USD, and annual labor cost savings can reach 2,900 USD.

- Feed cost: Daily feed cost savings are about 10USD, and annual feed cost savings can reach 3,600USD.

Customer Feedback

Customers highly praised the changes in the Poultry Farm in the Philippines after the use of the Layer Cage system. They said that the use of the new system not only improved the production efficiency of the chickens, but also greatly reduced the difficulty of management. Customers particularly emphasized the hygienic advantages and environmental improvements brought by the system, believing that this is crucial to ensure the health of the chickens and improve the quality of eggs.