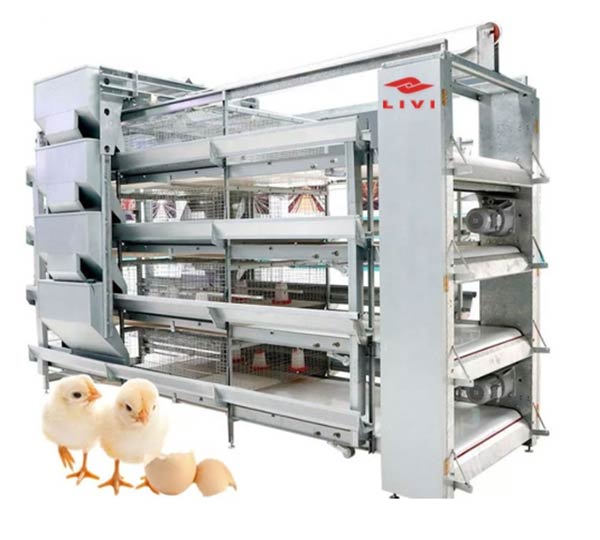

The integration of fully automatic chicken layer battery cages has become a cornerstone in modern poultry farming practices, especially in the context of larger chicken sheds such as those measuring 50x12x3.5m. This article delves into the significance, functionality, benefits, challenges, market availability, and future prospects of employing such systems in poultry farming operations.

Significance of Chicken Layer Battery Cages:

Chicken layer battery cages play a pivotal role in maximizing space utilization within the confined dimensions of a 50x12x3.5m chicken shed. These systems enable vertical stacking of layers, optimizing the available area and accommodating a larger flock size compared to traditional free-range methods.

Functionality of Battery Cage System in Poultry:

Battery cage system in poultry are designed with precision to cater to the specific needs of layer chickens. Each cage provides individual compartments for birds, ensuring their comfort, safety, and productivity. Automated feeding, watering, and waste removal mechanisms streamline operations, reducing labor requirements and enhancing efficiency.

Benefits of Utilizing Layer Cages:

a. Space Efficiency: By utilizing vertical space, layer cages maximize the capacity of a 50x12x3.5m chicken shed, allowing farmers to rear a larger number of birds within the same footprint.

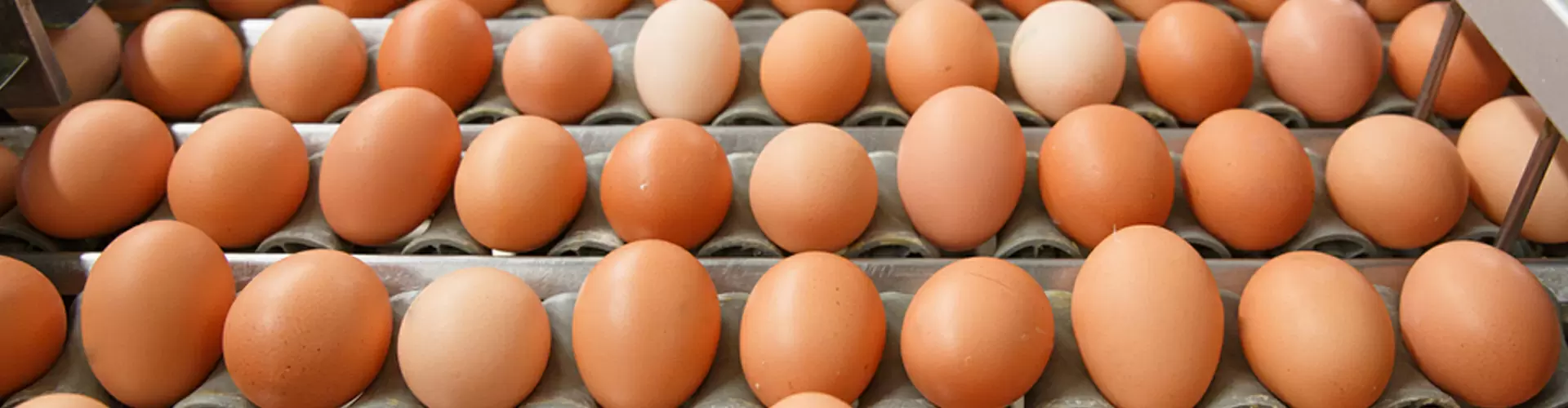

b. Improved Hygiene: Elevated cages prevent direct contact between birds and their waste, minimizing the spread of diseases and maintaining a cleaner environment.

c. Enhanced Egg Production: The design of battery cages facilitates efficient egg collection, reducing labor costs and minimizing egg damage, thereby maximizing overall egg production.

d. Labor Savings: Automation battery cage system in poultry significantly reduces the need for manual labor in tasks such as feeding, watering, and waste management, leading to cost savings for farmers.

e. Economic Viability: Despite the initial investment, the long-term benefits of increased productivity, reduced labor costs, and improved efficiency make battery cage systems a financially viable option for poultry farmers.

Layer Cages for Sale:

The market offers a wide range of chicken layer battery cages, catering to different farm sizes, budgets, and technological requirements. Farmers can choose from us offering customized solutions tailored to their specific needs and preferences.

| Model | Capacity | Cages Size(L*W*H) | Cell Quantity | Cell Size(L*W*H) | Surface | Material |

| A-96 | 96 Birds | 1.9M*2.3M*1.65M | 4 | 0.47M*0.36M*0.36M | Galvanized | Q235 |

| A-120 | 120 Birds | 2.2M*2.3M*1.65M | 5 | 0.44M*0.36M*0.36M | Galvanized | Q235 |

| A-128 | 128 Birds | 1.9M*2.5M*1.95M | 4 | 0.47M*0.36M*0.36M | Galvanized | Q235 |

| A-160 | 160 Birds | 2.0M*2.5M*1.95M | 5 | 0.39M*0.36M*0.36M | Galvanized | Q235 |

| A-200 | 200 Birds | 2.0M*2.8M*2.2M | 5 | 0.39M*0.36M*0.36M | Galvanized | Q235 |

How to set up the chicken layer battery cages in a 50x12x3.5m chicken shed:

When the chicken shed size is 50x12x3.5m, customers can use automated laying hen cages. There are 3 rows of A-type laying hen cages placed in the chicken house, with 23 groups in each row, totaling 69 groups. A layer cage with a maximum capacity of 160 chickens in a single group can be used, so the maximum breeding capacity of this chicken house can reach 11,040 laying hens.

Of course, customers can also choose H-type layer battery cages. We also have corresponding solutions that can be provided to customers.

Conclusion:

Fully automatic chicken layer battery cages are instrumental in maximizing productivity and efficiency in poultry farming operations, particularly within the constraints of a 50x12x3.5m chicken shed. The benefits of these systems in terms of space utilization, hygiene, productivity, and labor savings make them a compelling choice for modern poultry farmers. With continuous innovation and adherence to best practices, battery cage systems pave the way for a sustainable and prosperous future in poultry farming.