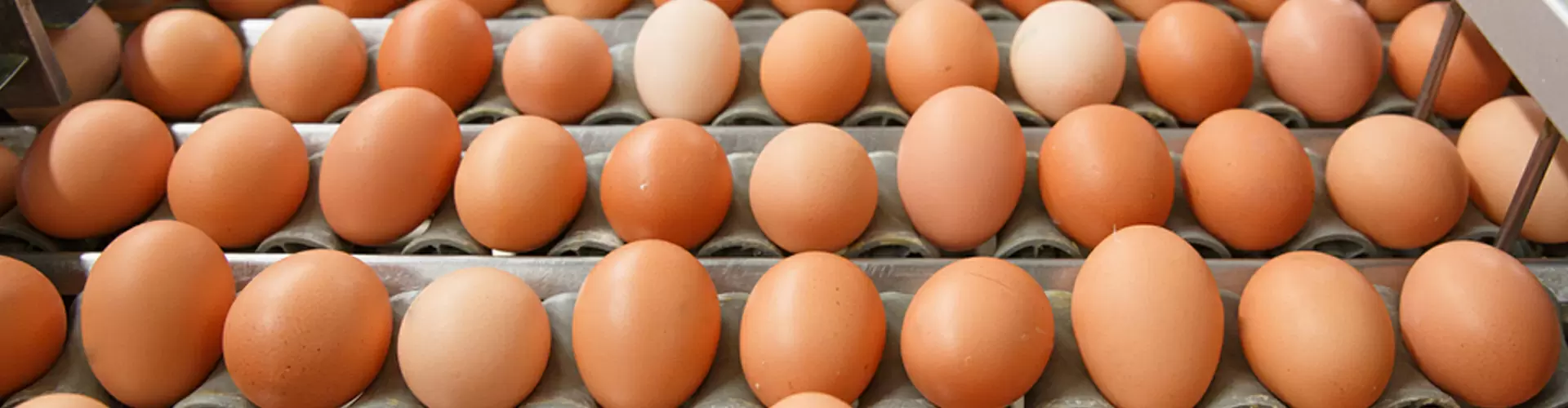

Amid Uganda’s booming chicken industry, a modern chicken farm has emerged as a benchmark in the industry with its 20,000-bird automatic A-type layer battery chicken cages.

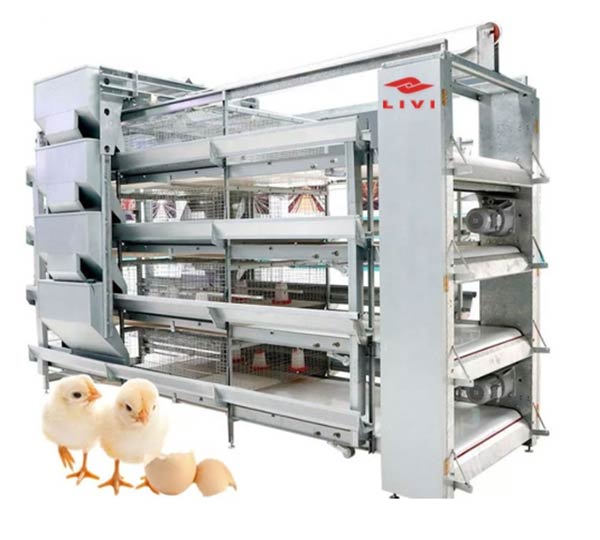

The person in charge of the chicken farm is an experienced chicken farmer who has been committed to using innovative technologies to increase production and efficiency. After researching various chicken equipment, he decided to invest in an A-frame chicken layer cage system.

The following are the reasons why this chicken farmer chose the A-type layer battery chicken cages:

Modern Design:These chicken coops are made of advanced materials ensuring durability and hygiene.

Automated System: Automatic waterer and feeder systems automate the feeding process and increase productivity.

Space Saving: The stacked design maximizes the use of space, allowing chicken farmers to raise a large number of chickens in a limited area.

Improve chicken health: The chicken coop is designed with the well-being of the chickens in mind, providing ample space and light. Since installing the Type A battery chicken cages, the chicken farm has seen significant improvements.

The chicken farmer is very satisfied with the Type A chicken cages. He said: “These chicken cages have completely changed my chicken farming business. They have increased production, reduced costs, and improved the health of the chickens. I strongly Would recommend these chicken coops to any chicken farmer looking to take their chicken business to the next level.

If you are interested in investing in an A-frame layer cages, contact us today. Our team will be happy to provide you with a customized solution to meet your specific needs.